The US Department of Energy’s Oak Ridge National Laboratory (ORNL) has received a license for a new method to 3D print components for nuclear reactors.

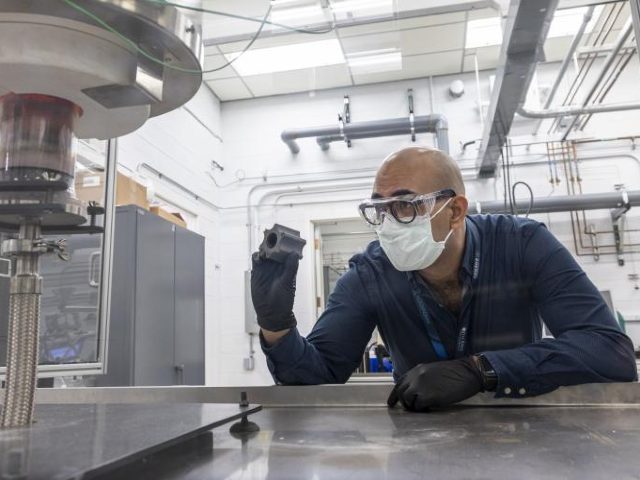

The license, provided by the Ultra Safe Nuclear Corporation (USNC), will allow ORNL to use an additive manufacturing technique to print refractory materials, which are highly resistant to extreme heat and degradation, into components with complex shapes needed for advanced nuclear reactor designs.

“It’s rewarding to see the transition from basic concept to a more mature technology that is actively being developed and deployed by our industry partners,” said Jeremy Busby, director of ORNL’s Nuclear Energy and Fuel Cycle division. “This is exactly the sort of impact that ORNL strives to make for our energy portfolio.”

Have you watched?

Webcast Recording: Additive Manufacturing “new opportunities for power plant operation

USNC will incorporate this method to boost their mission to develop and deploy nuclear-based, energy-generating equipment that is safe, commercially competitive and simple to use.

According to USNC, their refractory material of choice for nuclear reactor core components is silicon carbide, a high-temperature-resistant ceramic that has been tested and proven to be radiation tolerant. However, traditional machining of silicon carbide into parts for a reactor are so time-intensive and expensive that it’s nearly impossible.

Have you read?

Enel pilots 3D printing to repair geothermal components

GE awarded DoE grant to research 3D printing of wind turbine blades

The ORNL-developed method combines binder jet printing as the additive manufacturing technique and a ceramic production process called chemical vapor infiltration, which will allow USNC to make components more efficiently with desired complex shapes, such as fluid channels in a heat exchanger.

“This technology is ideal for manufacturing structure and core components for USNC’s advanced reactor designs,” said Kurt Terrani, USNC executive vice president.

“This is the holy grail of additive, that you can do things faster, that are in geometries that were previously very difficult or impossible with conventional manufacturing methods,” Terrani added.

USNC’s new Pilot Fuel Manufacturing, or PFM, facility will be located at the East Tennessee Technology Park in Oak Ridge, which is home to the former K-25 plant and mere minutes from ORNL’s main campus, allowing the energy company to easily continue its collaboration with ORNL.

“We look forward to continuing our strong relationship with ORNL,” said Francesco Venneri, chief executive officer of USNC. “Proximity to the lab and its world-class scientists and facilities allow us easy access to expertise in reactor core technologies and additive manufacturing, as well as the latest in radiation, fuels and materials research, all of which benefit USNC’s commitment to bring safe, reliable and secure nuclear energy to world markets.”

Visit the ONRL website for more detail about the technology inventors and the Manufacturing Demonstration Facility at ORNL.