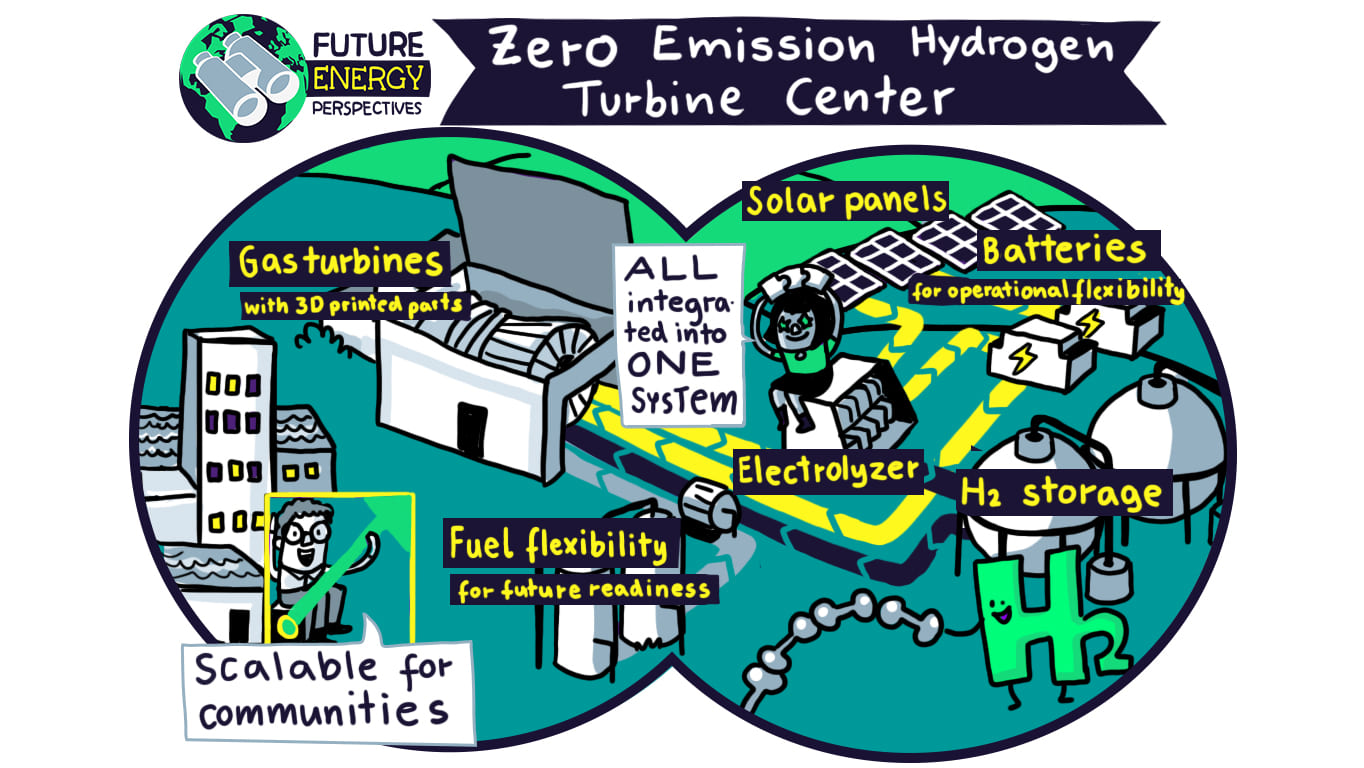

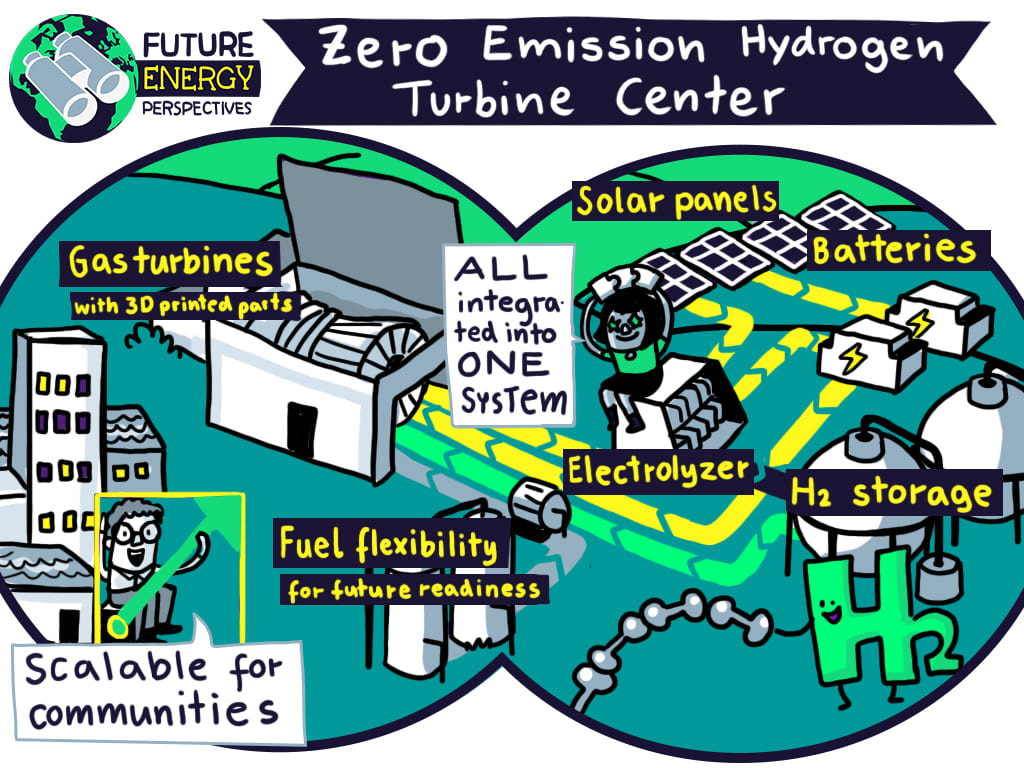

The Zero Emission Hydrogen Turbine Center, a Swedish hydrogen power plant project, is integrating gas turbines, renewables, energy storage and electrolysis in a flexible energy system of the future. Siemens Energy’s Åsa Lyckström explains how.

Sometimes you get to see the future happening right in front of your eyes – and it’s even better if you can actively help shape it.

At Siemens Energy in Finspång, Sweden, we’ve been working at the Zero Emission Hydrogen Turbine Center (ZEHTC) since 2018.

It’s a partially EU-funded demonstration plant designed to explore how green hydrogen can be produced and used for power generation and storage for industry and municipalities.

The concept is simple: using solar power and excess energy from testing mid-size industrial turbines, batteries are charged and hydrogen is produced.

The batteries help with operational flexibility and the hydrogen is then compressed and stored. When needed, it is used to power our gas turbine tests again.

Altogether, this creates a closed loop plant of the future, integrating major building blocks of our energy future.

The ZEHTC shows how Siemens Energy is driving innovation to support the development of a sustainable and flexible energy system.

This article is part of the ‘Future Energy Perspectives’ series, in which experts from Siemens Energy share their insights into how we can move towards a decarbonised energy system.

Getting the Zero Emission Hydrogen Turbine Center fully operational

In late December 2021, the ZEHTC became fully operational, as we connected the hydrogen storage to our gas turbine test centre at the manufacturing workshop.

After carrying out final tests and verifications of automation and safety features, it was ready in the configuration we had envisioned.

We are now gaining valuable first-hand experience from figuring out how the components work together, and with this knowledge, we can better support the decarbonisation of the power sector.

Also, by producing our own hydrogen at the ZEHTC, we’re now able to reduce our local carbon footprint when hydrogen replaces some of the natural gas for turbine testing.

Clean fuels as a path to the future

Why is such a demonstrator important today? When we think about the energy future, renewables are the predominant energy suppliers to power grids.

According to the International Energy Agency’s World Energy Outlook, by 2050 the global share of variable renewables in electricity generation is expected to reach some 40-70%.

Even though we cannot predict the exact number, it’s clear that renewables will play a central role in our future energy system. And given their intermittent nature, we also know that we need to bridge periods when the sun doesn’t shine, and the wind doesn’t blow.

Turbine-based power plants, with their operational and fuel flexibility, short ramp-up times, and ability to stabilise the frequency of the grid, can provide a good solution.

With such advantages, turbines will be reliable players in electricity grids, as they can ensure a stable and decarbonised electricity supply to many municipalities and industries for years to come.

And the ZEHTC shows that these power plants can especially do so by burning more and more clean fuels, such as green hydrogen. However, hydrogen is not the only option: also available are other fossil-free fuels, or e-fuels, such as e-methanol, and biofuels like biogas and biodiesel.

With these alternative fuels, power plants can now provide low-carbon or even CO2-free power plus heat solutions.

Gas turbines at the heart of it all

Because all this is so relevant today, it’s no surprise that the ZEHTC project isn’t purely a Siemens Energy project. It is partially funded by the EU and partners with local and regional Swedish government agencies, as well as two universities.

These collaborations are testament to the relevance of this work. We realistically demonstrate that renewables and gas turbines operating on hydrogen work hand in hand together with energy storage.

By doing so, we show how it can easily be scaled to meet the needs of many industries and municipalities around the world, helping them on their journey to decarbonise their own facilities, processes, and communities.

But before we talk in-depth about who may benefit from our research at the ZEHTC, let’s first look at some of the nuts and bolts of the project.

At the heart of it all, are the gas turbines. As the world moves away from fossil fuels, the turbines’ capability of handling hydrogen and other clean fuels becomes increasingly important.

At the ZEHTC demonstrator plant, we currently operate the turbines with up to 15% hydrogen. A full-scale energy system could fire much more hydrogen, depending on turbine type and fuel availability.

Have you read our other Future Energy Perspectives?

Kicking out coal and greening gas on the road to net zero

Karim Amin: Managing change to reach a decarbonised energy system

Burning 100% hydrogen

Today, several of Siemens Energy’s gas turbines can already burn up to 75% of hydrogen. This is valid for new turbines as well as retrofit units. At Siemens Energy, we are aiming to run gas turbines on 100% hydrogen by 2030 at the latest.

That ambition is enabled largely by additive manufacturing, also known as 3D printing. Our 3D-printed burners are optimised for burning hydrogen, which burns differently than other fuels. Also, these burners can burn other fuels in the mix or switch between fuels.

And there is already a plant in the works to realize this ambition. HYFLEXPOWER, also funded by the EU, is the world’s first integrated power-to-X-to-power hydrogen gas turbine demonstrator. Located at a paper factory in France, it will be firing 100% hydrogen in a Siemens Energy turbine by 2023.

Obviously, it’s not just Siemens Energy that sees the relevance of these hydrogen-ready turbines. Other major gas turbine OEMs are also planning to manufacture new gas turbines capable of firing hydrogen: in fact, most of today’s OEMs require that their gas-fired power plants be certified for hydrogen readiness.

At the heart of it all, are the gas turbines. As the world moves towards using hydrogen, the turbines’ capability of handling hydrogen and other clean fuels becomes increasingly important.

Åsa Lyckström

Hybrid system optimisation

Another important component in the ZEHTC is our hydrogen-producing electrolyser. Like all forms of electrolysis, it produces hydrogen by splitting water into hydrogen and oxygen with the help of electricity.

At ZEHTC, we apply proton exchange membrane (PEM) electrolysis. The hydrogen produced in the electrolyser is pressurised with a compressor and then stored. When needed, the hydrogen is used as fuel in gas turbines tests, co-fired with biogas and natural gas. To optimise the ZEHTC hybrid system, a battery and a control system is included for the plant.

Smart operation management is another important component of a hybrid power plant’s overall design and one that ZEHTC’s academic partner, Università di Bologna in Italy, has been working on. In a recent study, the research team there laid out a plant design optimizing the plant’s performance by determining, for instance, the best size of its various components.

A temporary bottleneck

From our work at ZEHTC, we know that there are challenges beyond our plant’s current design, among them being green hydrogen supply. Production capabilities are not yet widely available. Also, extensive infrastructure for distributing and storing hydrogen is still missing.

Therefore for hydrogen – and other low carbon fuels – to be available at scale, regulatory as well as financial incentives need to be put in place to ensure necessary investments.

Fortunately, this need is being recognised worldwide. Today numerous initiatives around the world are promoting the benefits of low carbon fuels, just as it was the case in the early days for solar and wind.

Collect the unique ‘Future Energy Perspective’ graphics.

Download ‘Zero Emission Hydrogen Turbine Centre: A closed loop of the energy future’

Municipalities, industries, and utilities

The need for the technology being pioneered at the ZEHTC is not in doubt. Writing in the International Journal of Hydrogen, Chalmers University of Technology in Sweden – one of the academic partners of the ZEHTC project – stated that gas turbines “have an important role to play in shifting electricity generation and providing capacity when carbon emissions are constrained to very low levels”.

So who is ready to adopt and implement these solutions? Among those interested in this kind of flexibility are cities, municipalities, and industries such as for instance chemical plants.

They all can benefit from small plants generating decentralised power, heating, and cooling, depending on their needs. And this allows them to push for net zero. Berlin, for example, intends to be CO2-free by 2050 and the list of companies and towns planning to do the same is growing rapidly.

Moreover, even large utilities can benefit from our work at the ZEHTC. Consider California. The state wants to achieve fossil-free power generation by 2045 and it has plenty of renewables.

Therefore, infrastructure producing green fuels as well as power plants and energy storage balancing the grid will be essential. So, it’s likely that regions such as California will develop hybrid systems similar to the ZEHTC at large scale, storing energy from the sunny days to be used during peak hours in the morning and evening when the energy demand is high.

Do your part to reach decarbonisation

That’s the path towards a decarbonized future we see here at Siemens Energy in Finspång. We do it for us, but also for others to be inspired by it. At the ZEHTC, we’re building knowledge and creating awareness for reliable and sustainable energy systems with hydrogen as the main carrier.

However, there’s no single solution that fits all needs. Hybrid systems will be sized and equipped differently in different regions.

But regardless of size, fuel-flexible turbine-based power plants using hydrogen – or other low carbon fuels in gaseous or liquid forms – will be an important building block of our energy future. We all need to prioritise net-zero goals and do our part to reach decarbonisation.

ABOUT THE AUTHOR

Åsa Lyckström is Sustainability Strategist at Siemens Energy and is one of the initiators of the Zero Emission Hydrogen Turbine Center. She has over 20 years of experience in the energy sector, working with gas turbine customers in Sweden and globally.

Watch the exclusive interview with Åsa Lyckström to learn more about the Zero Emission Hydrogen Turbine Center: