Clean fuels are expected to play a vital role in the energy transition. Erik Zindel of Siemens Energy takes a deep dive into hydrogen, its derivatives and biofuels to explain how they will help gas-fired power plants stay relevant.

Natural gas has been essential for decarbonising the energy mix.

The fast start-up and inherent flexibility of gas-fired combined-cycle power plants have long-supported the growing intake of intermittent renewable power generation into the grid.

And fuel switching from coal to gas has saved around 500 million tonnes (Mton) of carbon dioxide since 2010.

However, in the drive to a net-zero future, these impressive figures are not enough.

To meet international decarbonisation targets, all fossil fuels need to be phased out of the global energy mix. Currently, the International Energy Agency expects unabated natural gas to peak by 2030, with a steep 90% decline by 2040.

Scaling up potential

Given that world energy demand is projected to grow by nearly 50% over the next 30 years, simply swapping out gas for renewables is not practical.

Along with short-term energy storage like pumped hydro or batteries, clean fuels will be needed to secure supply during longer periods of low renewable energy availability and for seasonal storage of energy.

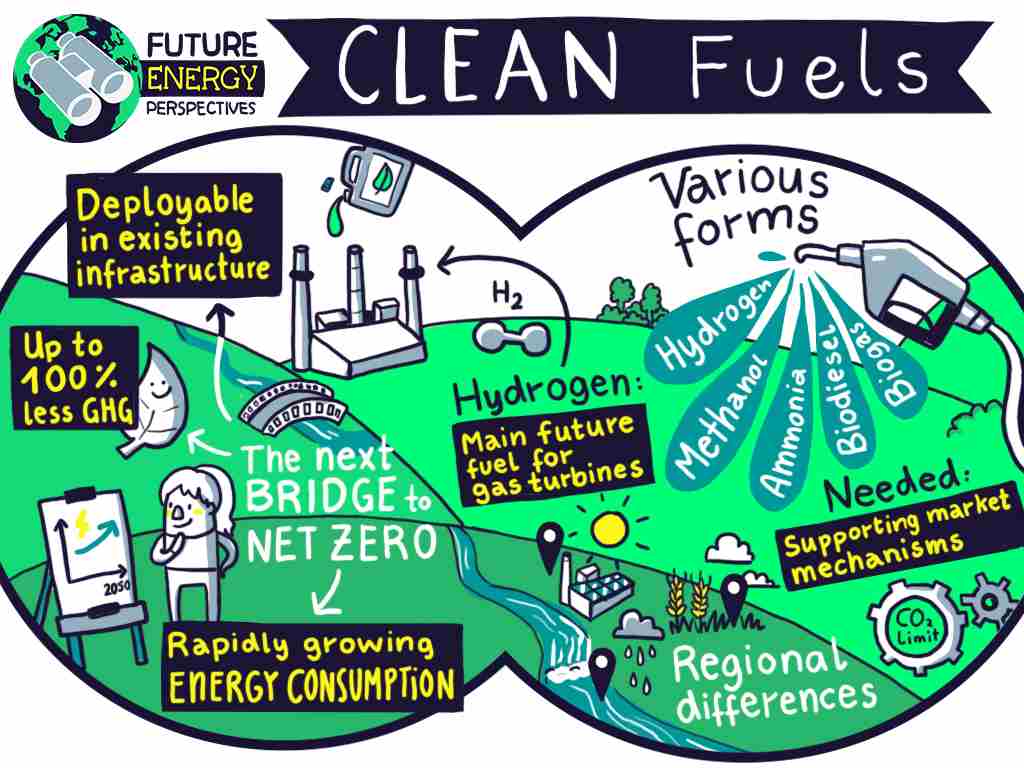

Made from renewable sources, clean fuels offer up to a 100% reduction of CO2 emissions, when compared to natural gas. Additionally, they’re deployable in existing infrastructures.

Clean fuels come in various forms: hydrogen; hydrogen derivatives such as e-methanol, e-methane, and e-ammonia; and biofuels like bioethanol, biogas and biodiesel.

They are typically derived from water and renewable energy, natural gas with carbon capture and storage, or organic matter, such as plants, timber, and agricultural and food waste.

Their use today is nascent, but depending on the availability of feedstock, infrastructure and investment, there’s a real potential for scaling up.

This article is part of the ‘Future Energy Perspectives’ series, in which experts from Siemens Energy share their insights into how we can move towards a decarbonised energy system.

Gothenburg goes green

Switching to clean fuels will allow many gas-fired power plants to continue providing residual and peaking power at a low or zero carbon footprint, which will be essential to securing investment and ensuring profitability amid changing taxonomy and investor sentiment.

One project has already demonstrated this shift is possible. At the Rya CHP district plant in Gothenburg, Sweden – the country’s second largest city – Göteborg Energi proved the suitability of Hydrotreated Vegetable Oil (HVO) with medium-sized gas turbines using DLE (Dry Low Emission) burners.

In November 2021, the plant ran on HVO for two days and showed that both start-up and stable operation are achievable. Göteborg Energi now plans to switch to green backup power in its gas turbines to provide district heating from entirely renewable or recycled sources by 2025.

Now let’s consider the key contenders in the realm of clean fuels.

Hydrogen

Green hydrogen can be produced by means of electrolysis using renewable energy and water.

Having the greatest potential for scale-up partly because water is the most abundant element, and due to its high-cost reduction potential, hydrogen is likely to be the main future fuel for gas turbines.

Governments are already throwing their weight behind it. To date, 17 European Union members have published strategies for electrolysis capacity, and more countries are also participating in the global CEM Hydrogen Initiative.

Modern gas turbines can be operated with a mix of hydrogen and natural gas from 5% to 100%. HYFLEXPOWER, a hydrogen CHP demonstration plant, will begin operations this year in Saillat-sur-Vienne, France. Operation with 100% hydrogen will be tested in 2023.

Also, the new combined heat and gas power plant HKW Leipzig Süd in Germany is expected to operate with 30-50% green hydrogen within a few years after starting commercial operation this year, with an overall target of 100% hydrogen by 2030.

For sure, using hydrogen in gas turbine power plants will require certain adjustments to existing turbines and power plants.

New infrastructure, such as a hydrogen pipeline network and underground caverns for storing hydrogen, will also be imperative.

Once these key elements are installed and running, the uptake is expected to be rapid. At any rate, progress this decade will be crucial to the later success of low-carbon hydrogen and hydrogen-based fuels.

Despite the huge potential, both hydrogen and e-ammonia still require robust supply chains and infrastructure before power plants can reliably switch to using them for fuel.

E-ammonia

A derivative of hydrogen, e-ammonia has real potential for energy storage, transport, and generation.

The compound doesn’t emit carbon dioxide when burned and could be used directly to fuel gas turbines. Some OEMs are already looking into ammonia combustion, but several roadblocks need to be eliminated.

One being a new combustor and exhaust treatment for managing the considerable levels of NOx emitted. Another issue is the fuel’s toxicity, which requires tight control of any unburned ammonia emissions.

When assessing the complete power-to-X-to-power cycle, e-ammonia is less efficient than hydrogen. However, it can be easily transported, meaning it has huge potential as a hydrogen carrier for intercontinental energy trade as well as remote regions without a pipeline infrastructure.

Once distributed, it can be ‘cracked’ to produce hydrogen and burned in a gas turbine, thereby eliminating the issues of burning ammonia directly.

Siemens Energy is developing ammonia-based technologies, such as an e-ammonia energy storage demonstrator in the UK. It uses renewable power to make the compound by combining hydrogen extracted from water and nitrogen from air. The technology could save millions of tonnes of CO2 a year.

Despite the huge potential, both hydrogen and e-ammonia still require robust supply chains and infrastructure before power plants can reliably switch to using them for fuel.

What’s more, they are both still relatively expensive compared to natural gas and today’s generation of biofuels, which require significantly less new infrastructure.

E-methanol

Among all hydrogen derivates, e-methanol is especially easy to synthesise, using a sustainable form of CO2.

Projected to be one of the top hydrocarbons in the e-fuel synthesis cascade, it is expected to be producible in large quantities, thus becoming widely available in the future.

It is also easy to transport and store in tanks. Although still an expensive fuel today, e-methanol can be easily burned in gas turbines requiring minimal equipment and facility adjustments.

Have you read our other Future Energy Perspectives?

Why storage is the Swiss Army knife of energy transition

Decarbonising heat: The hot topic we can’t ignore

Hybrid power plants: Tailoring technology to deliver decarbonisation

Zero Emission Hydrogen Turbine Center: A closed loop of the energy future

Kicking out coal and greening gas on the road to net zero

Biofuels

While hydrogen is undoubtedly set to be the dominant fuel of the future, biofuels can bridge the gap in the medium to short term and complement it in the longer term.

As biofuels can be produced via a closed-loop circular carbon process, they’re considered renewable and can cut greenhouse gas emissions by up to 86% when compared to gasoline. The IEA estimates the demand for biofuels to grow by 28% by 2026.

As technologies emerge, these fuels can be adopted in existing gas turbines and infrastructure with reasonable retrofit costs.

Depending on how it’s produced, the composition of biogas, for instance, can be very close to natural gas.

This can be seen in Finspång, Sweden, where Siemens Energy has been mixing biogas in its gas turbine test facilities. The hope is to inspire customers to start using low carbon fuels.

And it’s already happening. A new plant planned by Stockholm Exergi will be the first to use biogas or liquid biofuel in a combined cycle gas turbine.

Now let’s take a closer look at these biofuels.

Hydrotreated vegetable oil (HVO)

Hydrotreated vegetable oil’s usability with existing gas turbines has already been proven at the Rya CHP district plant.

As it’s produced by hydrocracking or hydrogenating vegetable oil, this fuel can be scaled by using waste, residues, and non-food crops, thereby making it sustainable as it does not compete with food production.

It provides a 77-83% GHG reduction, particularly when using waste oils – reaching the 80% threshold required to be considered sustainable in EU Taxonomy.

Currently produced in the US and the EU, with around 7.8 Mt, HVO’s availability is expected to increase. Costing around 48-104 €/MWh today, it’s anticipated to decrease in cost, being estimated at 29-79 EUR/MWh in the coming years.

Fatty acid methyl ester

FAME (Fatty Acid Methyl Ester), a generic chemical term for biodiesel derived from renewable sources, such as vegetable oils and animal fats, is mainly produced in the EU, US, Indonesia, Brazil and Argentina.

Today’s FAME volumes that are globally available are around 38 Mton – some four times greater than HVO.

However, scaling up production further may be hampered by the impure or poor quality of raw materials, such as waste and residues, which can’t be used for production.

Current pump diesel can contain up to 7% FAME. However, its use in power plants still requires some validation, which is ongoing. As it’s hydrophilic, it also does not have as good storage properties as HVO due to the risk of long-term fuel degradation.

Ethanol and dimethyl ether

Ethanol is produced by fermenting sugar to alcohol using conventional or waste food energy crops, residues or non-food crops, and is the most produced biofuel today, with 86 Mton mostly available from the US.

Though it still needs to be validated for use in power plants, it has very strong potential, as it can be easily produced using waste and residues and exhibits good storage properties.

Lastly, advanced fuel dimethyl ether (DME), produced via gasification of biomass, can offer 86-89% GHG savings and has the potential for use in gas turbines. Although there’s no large-scale production now, this could change as biomass gasification plants commercialise.

Collect the unique ‘Future Energy Perspective’ graphics.

The location factor

Location is highly important in the usability of clean fuels in the process of replacing gas. Particularly, regional supply, existing infrastructure and land resources, weather conditions and competing market factors are essential parameters.

Markets with abundant renewable energy resources, such as Sweden, are well placed for scaling up green hydrogen production.

As the Rya CHP district plant in Gothenburg shows, areas with a high forest area per capita, can lead the way towards adopting clean fuels.

Other markets with access to existing infrastructure – such as hydrogen gas grids in Europe, the UK or US – will find it easier to adopt hydrogen as a clean fuel.

In comparison, liquid renewable fuels would be best suited to island grids and decentralised applications lacking this infrastructure.

Market mechanisms

As with all green energy to date, clean fuels are unlikely to scale up quickly enough by the end of the decade without supporting market mechanisms, such as upper limits on CO2 emissions for energy generation.

Also, the EU’s upcoming carbon border adjustment mechanism for products imported into its market could influence the decarbonisation of the energy assets of its trading partners.

No doubt, the road to net zero is filled with great expectations as well as uncertainties – but is it at all achievable within an acceptable timeframe? No one knows.

Navigating these unknowns is a huge challenge, particularly for gas-fired power plants. Here clean fuels offer an opportunity to future-proof these assets.

In the long run, clean fuels, such as green hydrogen, are expected to become more economically affordable than the grey fossil-based versions we mostly use today. Thus, clean fuels will play a vital supporting role to renewables during the energy transition.

Watch the exclusive interview with author Erik Zindel to learn more about his vision on the role of clean fuels in the energy transition.

ABOUT THE AUTHOR

Erik Zindel is Vice-President of Generation Sales – Hydrogen at Siemens Energy and currently leads the company’s initiative for hydrogen combustion in gas turbines. He is also involved in all other aspects of its hydrogen strategy. Erik has worked for Siemens Energy in various positions all around the globe for the last 27 years.